The process of making bras is an intricate journey that combines artistry, engineering, and precision. From fabric selection to the final stitching, every step of the process is carefully planned to ensure that the final product is both functional and comfortable. So, how exactly are bras made, and what goes into creating the perfect fit for every body type?

The process of bra-making is a meticulous journey that includes several crucial stages, each contributing to the creation of a comfortable, well-fitted, and long-lasting garment. It begins with selecting the right materials, which include fabrics, elastics, and hardware like hooks and straps, chosen for their softness, durability, and stretchability. Next, designing patterns ensures the bra’s structure and fit, taking into account different styles, sizes, and support needs. Once the patterns are finalized, the fabric is carefully cut to precise measurements to avoid wastage and ensure uniformity. The assembly stage involves stitching together the various parts, such as cups, straps, and bands, while incorporating features like padding or underwires. Finally, testing is done to check the fit, functionality, and quality of the bra, ensuring that it provides the desired level of comfort, support, and durability. Each stage is crucial to ensure the final product meets the highest standards of performance and wearer satisfaction.

Many of us wear bras every day but rarely stop to think about the process that goes into making them. Whether it’s a simple cotton bra for daily use or an intricate lace design, the process is anything but simple. In this article, we’ll explore how bras are designed and produced, diving into the steps that transform raw materials into the comfortable, supportive garments we rely on.

✖

Bras are made from a variety of materials, including fabric, elastic, padding, underwires, and hooks. It’s a combination of different elements that makes a bra functional and comfortable.

✖

Different types of bras—such as sports bras, lace bras, and strapless bras—require different manufacturing techniques. The materials, patterns, and designs change to suit their specific functions and aesthetics.

Understanding the Bra Manufacturing Process

The making of a bra begins long before the fabric is cut or sewn. It starts with a design concept that takes into account not only the appearance of the bra but also the comfort, fit, and function. Designers work closely with pattern makers to ensure that the final product will provide the necessary support and look aesthetically pleasing.

Once the design is finalized, materials are selected based on the intended function of the bra. For example, bras designed for sports require highly supportive, moisture-wicking materials, while everyday bras prioritize comfort and durability. Aesthetic elements, like lace or satin, are chosen for their appeal but may be mixed with more functional fabrics for added support.

After the design and material selection, manufacturers prepare the patterns that will guide the fabric cutting. Patterns are carefully created to fit different sizes and body shapes, ensuring that each bra will have the perfect structure.

This process involves detailed measurements to ensure that each piece of fabric is cut precisely to fit the pattern. Afterward, it's sent to production facilities, where skilled workers begin assembling the components.

✔

Designing bras often starts with computer-aided design (CAD) software. This allows the designer to visualize the structure and make necessary adjustments before physical patterns are created.

✖

While mass production is common, bras are still designed and adjusted for specific sizes, styles, and purposes. Even in large-scale manufacturing, adjustments are made to ensure proper fit and support.

The Materials That Make a Bra

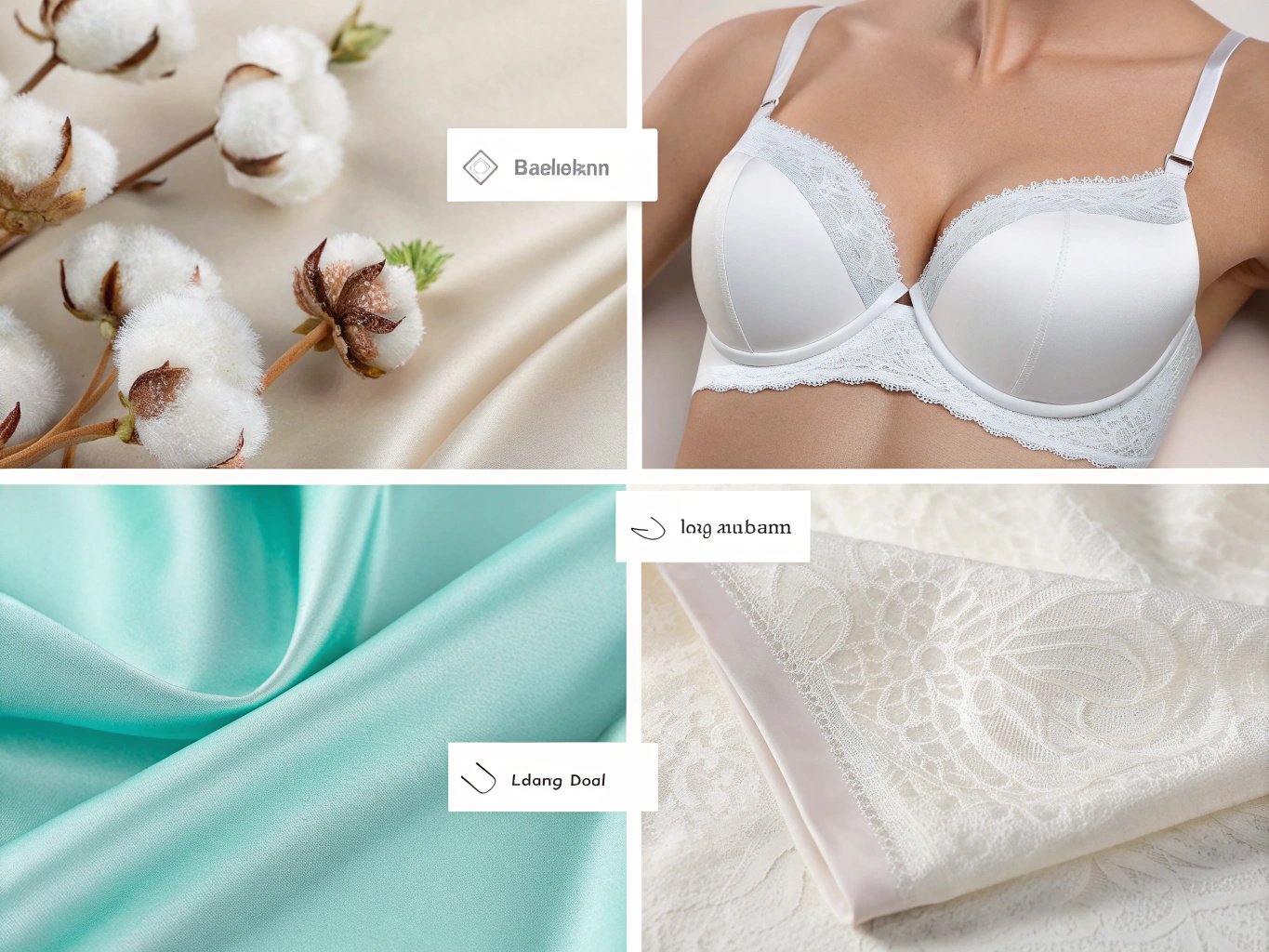

Bras are made from a combination of fabrics, each chosen for its particular characteristics. Some fabrics are chosen for their softness, others for their elasticity, and some for their visual appeal. Here are some of the common materials used in bra production:

- Cotton: Known for being breathable and comfortable, cotton is often used for everyday bras. It’s soft against the skin and naturally moisture-wicking.

- Microfiber: This fabric is lightweight, smooth, and often used in seamless bras. Microfiber is durable, breathable, and resistant to shrinking.

- Satin: Often chosen for its elegant appearance, satin gives bras a smooth, shiny finish. It’s frequently used in more delicate, luxurious designs.

- Lace: Lace adds a delicate touch to bras, often used in lingerie. It’s sheer and elegant but typically needs to be paired with other materials to provide support.

- Spandex/Elastic: Essential for stretch, spandex and elastic are used in bands, straps, and the cups themselves to provide shape, fit, and comfort.

- Underwire: Many bras include underwires made of steel or plastic for added lift and support. This component is critical for bras that offer more structured support, such as push-up bras or underwired bras.

Each of these materials is selected with the final purpose of the bra in mind—whether that’s providing comfort for all-day wear, support for physical activities, or an aesthetic appeal for evening wear.

Design and Pattern Making in Bra Production

Once materials are selected, designers move on to the pattern-making stage. This is one of the most critical steps in bra production because it defines how well the bra will fit and support the body. A pattern is essentially a template that outlines the exact measurements and pieces of fabric that will be used.

A typical bra pattern consists of several components: the band, the cups, the straps, and any additional pieces like side support or the center gore. Designers consider factors like the type of closure (hook-and-eye or front clasp), the placement of seams, and the overall fit when creating the pattern.

After the initial pattern is designed, a sample bra is sewn together. This sample undergoes rigorous testing for fit, comfort, and appearance. If the bra does not meet the required standards, designers modify the pattern. Sometimes the pattern goes through multiple iterations to achieve the perfect fit.

Once the pattern is finalized, it is sent to production, where it will be used to cut the fabric into the appropriate shapes for assembly.

The Assembly Process: From Fabric to Fit

With all the pieces of fabric cut and ready, the assembly process begins. Skilled workers stitch the fabric components together, ensuring that each piece aligns with the pattern and fits correctly. The band, cups, straps, and underwires are sewn together in a careful and deliberate process.

One of the most crucial parts of the assembly is the attachment of the hook-and-eye closure. This closure is essential for adjusting the bra to fit the wearer. Straps are sewn in place, and padding (if used) is added to the cups. Once everything is stitched together, the bra is turned right-side out, and the final touches are made.

The assembly stage also includes attaching any decorative elements, such as lace trims or satin finishes, which add aesthetic appeal to the bra. After all the pieces are stitched, the bra undergoes final quality control checks before moving on to the next stage.

Quality Control and Testing

Once the bras are assembled, they are thoroughly inspected to ensure they meet quality standards. The bras are tested for fit and durability by being worn on models of different sizes. Any defects in stitching, fit, or appearance are flagged during this process.

Additionally, bras are subjected to wear-and-tear tests, including stretch tests, washing tests, and stress tests to ensure that they maintain their shape and function after repeated use. Any bras that fail the tests are sent back for rework, and only those that pass the final checks are approved for distribution.

Conclusion

The process of making bras is both complex and fascinating. From the design concept to material selection, pattern making, assembly, and quality control, each step is crucial to creating a high-quality product that provides comfort, support, and durability. Whether you're wearing a simple cotton bra or a luxurious lace design, understanding how bras are made can help you appreciate the craftsmanship and engineering that goes into creating the perfect fit. Next time you put on a bra, you'll have a new level of respect for the process that turns raw materials into a functional, well-fitting garment.